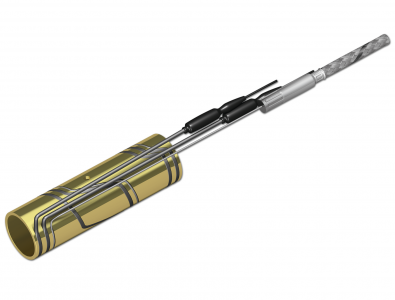

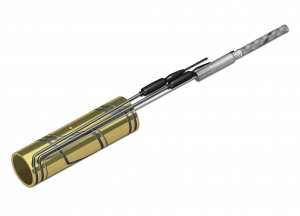

Cartridge heaters

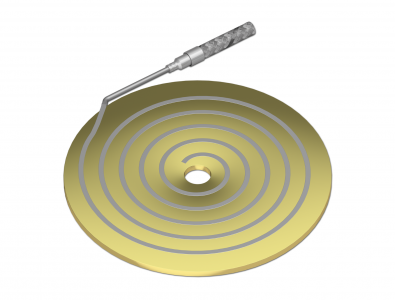

CETAL offer a large range of coil heaters starting with Micro (type WRP/F 1,0 x 1,6) up to Maxi (type WRP 4,8 x 8,6) with different lenghts and diameters.

Brass-coil heaters or coil heaters with clamping mechanism as heating elements for different applications.

For heating applications

- Hot runner nozzles with and without wattage distribution

- Small hot runner distribution plates

- Sealing bars and jaws for packaging machines

- Machine nozzles for plastics and die-casting industries

Multi-purpose and economical with a variety of

- Wattages, surface loads and customized heat distribution

- Wall thicknesses and mounting options

Range of clamping options

- Undersized inner diameter for open coiled heater fitting

- Lower thermal expansion with reflection tube

- Tight fitting with axial screw clamping band

- Tangential screw clamping

With hotslot®, which is based on the proven principle of usual coil heaters, CETAL offers an excellent heating solution for nozzles.

The coil heater/Mini (wall thickness of a minimum of 2 mm according to type) or Micro (wall thickness of a minimum of 1.3 mm according to type) is pressed in a slot thus the hotslot is especially space-saving.

The run of the slot with or without thermocouple as well as the power distribution can be individually determined.

Main applications

- Pressed-in coil heater with user-defined groove profile

- Reproducible power distribution

- Minimal wall thickness for reduced clearances

- Lowest power available in the middle of a nozzle

- Brass as cylinder raw material

- Same connection options as hotspring coil heaters

CETAL offers a large range of catridge heaters (Standard or customized) to cover many applications especially in Plastic industry.

Excellent knowledge, high-quality materials as well as the outstanding manufacturing guarantee long life and excellent product features.

By intensive cooperation – also with special applications – CETAL gives again and again innovative impulses to its cartridge heaters with new technical features (e .g. humidity-resistant connection area).

Please find in our brochures a large range of standard products.

Application examples

- Injection moulding – Internal heating of nozzles

- Hot runner systems – Heating of manifolds

- Packaging industry – Heating of welding bars

- Packaging industry – Heating of hot stamps

- Textile Industry – Heating of cutting knives

- Paper Industry – Heating of stamping rolls

- Laboratories – Heating of analytical equipment

As well as a large range of heating elements and temprature control units, CETAL also offers a large range of thermocouples and RTDs:

Areas of application:

- Plastics industry

- Mechanical engineering

- Steel industry

- Chemical industry

- Ceramics and glass industry

- Energy industry

- Pharmaceutical industry

- Furnace systems

- Engine test benches

- Packaging industry

- Automotive industry

Thermocouples

A thermocouple consists of two wires made of different materials that, due to the thermoelectric effect, produce a voltage from which the temperature can be derived.

Depending on the desired application temperature, various thermocouples are available to choose from.

Type J iron/cupro-nickel acc. to DIN EN 60584 & ANSI 96.1

Type L iron/cupro-nickel acc. to DIN 43710

Type K nickel-chromium/nickel acc. to DIN EN 60584 & ANSI 96.1

Type K nickel-chromium/nickel acc. to DIN 43710

However, the following thermocouple types are also available from us on request:

- Type E, R, S, and Tacc. to DIN EN 60584 & ANSI 96.1

- Type Nacc. to DIN EN 60584

- Type Bacc. to ANSI 96.1

- Type Uacc. to DIN 43710

The measuring point can be manufactured as both grounded and ungrounded. You can select the classification tolerances according to class 1 or class 2.

Key features and advantages:

- Also suitable for use in higher temperature ranges, such as types B, R, and S, which are temperature-resistant up to 1600°C

- Short response time to temperature changes for fast reactions in the controlled system, especially with an ungrounded measuring point

- Robust against mechanical stress and less sensitive than, e.g., RTDs to shocks and vibrations

- Very widespread and well-known sensor type

- Inexpensive

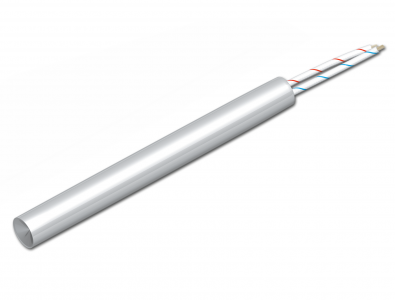

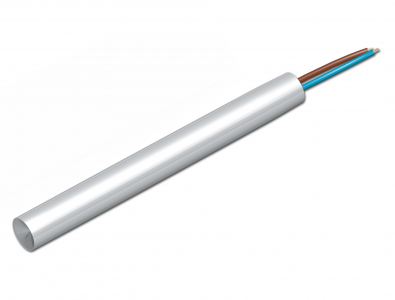

RTDs

RTDs are used to measure temperature in many sectors of industry. Here, an ohmic resistor is used as a temperature sensor. Its resistance value is temperature-dependent. Platinum has established itself as the chosen resistive material. The most frequently used platinum alloy is known as Pt100, which we manufacture according to DIN EN 60751.Other available sensor types are, for example:

- Pt100

- Pt500

- Pt1000

- Ni100

- Ni120

- Various NTC sensors

In order to minimize the effects of the cable resistances and their temperature-dependent variations, we manufacture sensors with connections for three- and four-cable circuits, as well as those with a two-cable connection.

You can select the classification tolerance according to class A and class B.

Key features and advantages:

- Higher measurement accuracy than thermocouples

- Optimum long-life stability

- High chemical resistance as a result of the platinum

Temperature Sensor Types

All sensor types can in principle be supplied as a thermocouple and an RTD.

Mineral Insulated Thermocouples/RTDs

Mineral-insulated thermocouples/RTDs, also known as sheath thermocouples/RTDs, represent a special type of temperature sensors. They consist of a flexible, thin-walled, mineral-insulated cable that allows a long service life thanks to its shock-proof construction. They differ from other temperature sensors in their compact construction, fast response times to temperature changes, and flexibility, which allows their introduction into hard-to-reach measuring points.

The materials used (1.4541 and 2.4816) mean that the sleeve welds and solders well, has optimum strength properties at high temperatures, and meets the typical requirements in environments with gaseous and liquid media.

Connectors and compression fittings are available in numerous varieties.

Connection types:

- Open ends

- Connection heads

- LEMO connectors

- Compensation connectors

- Mini compensation connectors

Numerous other connection types on request.

Frequent areas of application:

- Hot-runner nozzles

- Flue-gas analysis

- Furnace construction

- Steelworks

- Laboratories

- Test facilities and test benches

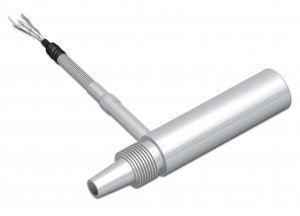

Angle Thermocouples and RTDs (Types PWF 1 and TEF 12)

Suitable for measuring temperature on injection and die-cast molds in plastic and zinc die casting. Angle sensors are beneficial wherever a straight cable outlet is not possible or not wanted, e.g. for space reasons. The connection lead’s bend-protection spring serves as mechanical protection. The sensor is fastened in place with, e.g. a compression fitting or a screw-in thread.

Insert Surface Thermocouples and RTDs (Types TEF 2/PWF 2)

Insert surface sensors are used preferentially for temperature measurements in solid objects, e.g. hot-glue applicator heads or welding/sealing jaws of packing machines.

The cable’s junction with the protective tube is strain-relieved. The stainless-steel protective tube protects the measuring point from chemical influences and mechanical damage.

The sensor is fastened in place by direct insertion into the bore hole or with a flange.

Thermocouples and RTDs with Bayonet Cap (Types TEF or PWF 4, 11, 16, 20)

Thermocouples and RTDs with a bayonet cap are used preferentially for temperature measurements in solid objects, slide bearings, and tools, e.g. for injection molding or extrusion of plastics in the plastics industry.

The probe tip’s special shape means these temperature sensors are suitable for use in plane and tapered bore holes.

The stiff compression spring made of rust- and acid-resistant stainless steel, which simultaneously acts as bend protection, ensures that the probe tip exerts consistent contact pressure in the bore hole. The installation length can be varied by twisting the bayonet cap.

The bayonet cap is available in several diameters.

Screw-in adapters are available in various designs.

Ring Thermocouples (Types TEF 13/30)

Ring thermocouples were developed for temperature measurement on surfaces. They can be attached easily with a screw and are suitable for numerous areas of use, e.g. hot-runner manifolds.

Surface Thermocouple (Type TEF A)

For temperature measurement on pipelines and all cylindrical shapes. The sensor is welded or soldered into place. The connection lead’s bend-protection spring serves as mechanical protection.

Clamping Band Thermocouple (Type TEF SP)

Common names also include ‘pipe-clamp thermometer’ and ‘pipe-clamp RTD’. These are used to determine the temperature on pipelines and cylindrical bodies. They are attached using the adjustable clamping band. The connection lead’s bend-protection spring serves as mechanical protection.

Flange Mounted Thermocouple (Type TEF 68)

For temperature measurement on tools, e.g. hot-runner manifolds.

This sensor is especially economical in terms of space and can be attached easily to the flange with a screw. The bend-protection spring on the connection lead serves as mechanical protection.

Automotive industry

Mineral Insulated Thermocouple / Mineral Insulated RTD

General applications

- Engine compartment

- Catalytic converter

- Exhaust pipe

Mineral Insulated Screw-in Thermocouple / Mineral Insulated Screw-in RTD

General applications

- Engine compartment

- Turbocharger

- Oil pan

- Exhaust pipe

Wire Thermocouple

General applications

- Difficult accessible areas with limited space and/or if fast response times

Self-Adhesive Surface Thermocouple

General applications

- Quick, space-saving and uncomplicated temperature measurement on surfaces, e. g. on auto interior and boots

Spring Thermocouple / Friction Thermocouple

General applications

- Temperature recording on the brake disc or other rotating surfaces

Insert Thermocouple

General applications

- Temperature recording in the brake disc (For installation into the brake disc)

Terminal Strip

General applications

- Consolidates several connection leads to reduce wiring effort and save space

CETAL offers a wide product range for applications in the casting industry (e. g. hot chamber casting).

The Sealed Nozzle Heater (type GMH) based on the heating with a coil heaterg Maxi with power distribution offers the possibility of an equal heating of the mass channel.

The densely welded sealed system grants besides resistance against penetrating material, high energy savings (up to 60 % towards traditional heating) as well as shorter cycle times and material savings (shorter sprue bar and shorter cycles by deep immersion into the tool).

Accessory

With the corresponding accessory such as Isolite-Spray or insulation tubes the effectivity of the inserted heating element can be considerably increased. Therefore CETAL offers a wide range of accessory corresponding to its products.