Straight heaters

Product overview

- Power up to 30 kW per heating element

- Watt density from 0.1 to 20 W/cm²

- Voltage max. 750 V

Advantages

- Reliability and robustness of the heating element. High quality raw material.

- Large range of materials and options according to customer process and conditions of use.

- Benefit from CETAL’s 50 years of experience as designer and manufacturer!

Operating conditions

- Normal (non-ATEX)

- Hazardous areas (ATEX/IECEx) and NEC 505

- Fluid/solid: from -270 °C (3 K) to 1000 °C

- Corrosive environment

Water

- Stagnant water, max load 8 – 12 W/cm², material: copper, 321, 316L

- Circulating water, max load 10 – 16 W/cm², material: copper, 316L, incoloy 800, incoloy 825

- Boric water, max load 8 W/cm², material: 316L

- Boiler water, max load 8 – 16 W/cm², material: 316L, incoloy 800, incoloy 825

- Chlorated water, max load 6 W/cm², material: incoloy 825

- Sea water, max load 3.5 – 6 W/cm², material: incoloy 825, inconel 600

- Demineralized water / deionized / distilled / softened, max load 4 – 6 W/cm², material: 316L, incoloy 800, incoloy 825

- Domestic hot water, max load 4 – 8 W/cm², material: copper, 316L, incoloy 825

- Caustic water (2%, 10%, <30%, 70%), max load 2.3 – 7 W/cm², material: 316L, incoloy 825, inconel 600

Oil

- Fuel oil pre-heating, light fuel oil, C fuel oil, max load 1 – 2 W/cm², material: 321, 316L

- Heavy fuel, max load 0.5 – 3.5 W/cm² acc to grade, material: 316L

- Gasoline, kerosene, max load 3 – 3.5 W/cm², material: 316L

- Machine oil SAE 10, 30, 40 & 50, max load 2 – 3.5 W/cm², material: 316L

- Mineral oil , max load 0.5 – 3.5 W/cm² acc to temp, material: 321, 316L

- Lube oil, max load 2.3 W/cm², material: 321, 316L

Acid & corrosive fluid

- Acetic acid, max load 6 W/cm², material: 316L, incoloy 825

- Boric acid, max load 6 W/cm², material: incoloy 825

- Chloric, hydrofluoric, nitric, sulphuric acid, max load 1.5 W/cm², material: teflon coat

- Boric acid, max load 6 W/cm², material: incoloy 825

- Alkaline bath, max load 6 W/cm², material: 321 (no corrosive compound), 316L

- Phosphate bath, max load 4 W/cm², material: 316L, incoloy 825

Glycol

- Ethylene glycol, propylene glycol, 4 – 8 W/cm² acc. to concentration, material: 321, 316L

Others

- Asphalt, tar, and other heavy or highly viscous compounds, max load 0.5 – 1.5 W/cm², material: 316L

- Milk, max load 0.3 W/cm², material: 316L

Gas

- Air, max load 0.1 – 8 W/cm² acc. to sheath temp., material: 321

- Circulating air, max load 0.1 – 8 W/cm² acc to sheath temp., material: 309

- Natural gas, max load 0.1 – 8 W/cm² acc. to sheath temp., material: 321, 316L

- Argon, nitrogen, load acc. to sheath temp., material: 321, 316L, incoloy 825, inconel 600

- Propan, butane, load acc. to sheath temp., material: 321, 316L

- Oxygen, hydrogen, load acc. to sheath temp., material: 316L

Solids

- Aluminium, brass, bronze cast in, max load 4 – 15 W/cm², material: 309

- Copper-nickel cast in, max load 5 – 10 W/cm², material: 309

- Oxychloration, max load 3 W/cm², material: incoloy 800, incoloy 825

- Calcination, max load 3 W/cm², material: incoloy 800, incoloy 825

- HC regeneration, max load 2 W/cm², material: incoloy 800, incoloy 825

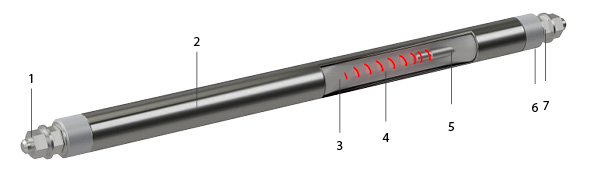

Technical description

The watt density, tube diameter and the tube sheath are chosen to optimize the reliability and robustness (corrosion, temperature) of CETAL equipments.

Technologies

- Tubular heating element

Tube diameter & material

- Tube diameter: 6.5 / 8.5 / 10 / 13.5 / 16 mm

- Tube material:

- Stainless steel: AISI 321 (1.4541) / AISI 316L (1.4404) / AISI 309 (1.4828)

- Others: Incoloy 800 (1.4876) / Incoloy 825 (2.4858) / Inconel 600 (2.4816)

- Titanium

- Specific coating: Teflon™ (PTFE) / Halar®

- Tube type: sealed tube, seamless tube (on request)

Manufacturing

- 100% of the components come from our high-quality suppliers from Europe

- 100% manufacturing in CETAL factory

- Connection terminals

- Tube

- Insulation : magnesia oxyde (Mg O), to secure optimized heat transfer and electrical insulation.

- Resistance wire: Made of Nickel Chrome 80/20, it is the active part of the heating element (Joule effect)

- Cold length

- Sealing material: Keeps out external moisture. Different types (silicon, resins, cement) are used depending on the industrial application, the external medium and temperature

- Output insulation: Made of steatite ou corundum, it provides dielectric insulation (creepage distance, distance in the air).

CETAL offers a large range of non heating parts / cold parts to meeting any customer specification.

The table below shows the different cold parts available by diameter and length.

| Tube Ø | 6,5 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 8,5 | ||||||||||

| 10 | ||||||||||

| 13,5 | ||||||||||

| 16 | ||||||||||

| Ø tige de sortie | Ø 2 | Ø 3,5 | M4 x 0,7 | M5 x 0,8 | M6 x 1 | M8 x 1,25 | ||||

| Lg NCH | Matière Acier | Matière Inox | Matière Acier | Matière Inox | Matière Acier | Matière Inox | Matière Acier | Matière Inox | Matière Acier | |

| 35 | ||||||||||

| 40 | ||||||||||

| 45 | ||||||||||

| 55 | ||||||||||

| 75 | ||||||||||

| 65 | ||||||||||

| 95 | ||||||||||

| 105 | ||||||||||

| 135 | ||||||||||

| 150 | ||||||||||

| 180 | ||||||||||

| 205 | ||||||||||

| 200 | ||||||||||

| 225 | ||||||||||

| 235 | ||||||||||

| 260 | ||||||||||

| 300 | ||||||||||

| 330 | ||||||||||

| 365 | ||||||||||

| 415 | ||||||||||

| 420 | ||||||||||

| 445 | ||||||||||

| 500 | ||||||||||

| 505 | ||||||||||

| 530 | ||||||||||

| 620 | ||||||||||

| 775 | ||||||||||

| 800 | ||||||||||

| 1000 | ||||||||||

| 1340 | ||||||||||

| Materials | |||||||

| Copper | Austenitic steel | Nickel alloy | |||||

| AISI code | 321 | 316 L | 309 | INCOLOY 800 | INCOLOY 825 | INCONEL 600 | |

| DIN code | 1.4541 | 1.4404 | 1.4828 | 1.4876 | 2.4858 | 2.4816 | |

| Usuals diameters | |||||||

| 6,5 | |||||||

| 8,5 | |||||||

| 10 | |||||||

| 13,5 | (1) | ||||||

| 16 | (1) | (1) | |||||

| limit temperature of use | |||||||

| 250 °C in the air | 750 °C | 750 °C | 1000 °C | 950 °C | 950 °C | 950 °C | |

(1) Seamless tube on stock

| Tube diameter | Max voltage |

| 6.5 | 400V |

| 8.5 | 415V |

| 10 | 500V |

| 13.5 | 690V |

| 16 | 750V |

- Wire restance tolerance: -5% and +10% of the nominal resistance value

- Power tolerance < 100W: -/+10%

- Power tolerance > 100W: +5% – 10%

|

Sheaths |

Very high quality rolled, welded or seamless tube manufactured and inspected according to standards ASTM-DIN ou NFA 49-147 |

|||

|

Forming |

The heating elements are available in a variety of shapes adapted to the use circumstances defined in the specifications or by the customer |

|||

|

Tolerances |

Diameter: |

6.5 ± 0.1 mm |

13.5 ± 0.1 mm |

|

|

8.5 ± 0.1 mm |

16 ± 0.1 mm |

|||

|

10 ± 0.1 mm |

||||

|

Length: |

± 1 % with + 5 mm minimum |

|||

|

Standard material: |

The dimensions in the table are maximal Dimensions intended to prevent assembly problems |

|||

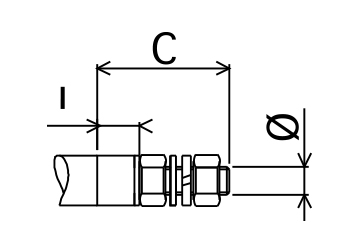

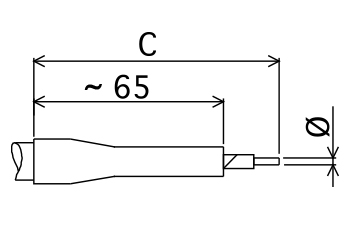

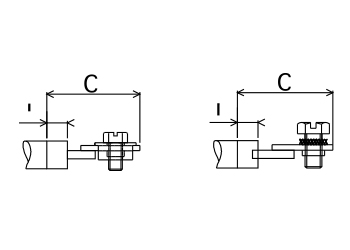

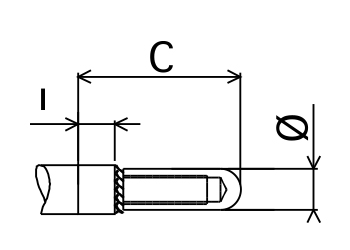

Type B 100

- THREADED STEEL OR STAINLESS STEEL ROD

| Dimensions | Sheaths Ø | ||||||

| Ø mm | C | I | 6.5 | 8.5 | 10 | 13.5 | 16 |

| M4 x 0.7 | 20 | 5 | |||||

| M4 x 0.7 | 20 | 5 | |||||

| M4 x 0.7 | 20 | 5 | |||||

| M5 x 0.8 | 30 | 10 | |||||

| M5 x 0.8 | 30 | 10 | |||||

| M6 x 1 | 35 | 10 | |||||

| M6 x 1 | 35 | 10 | |||||

| M8 x 1.25 | 35 | 10 | |||||

| M8 x 1.25 | 35 | 10 | |||||

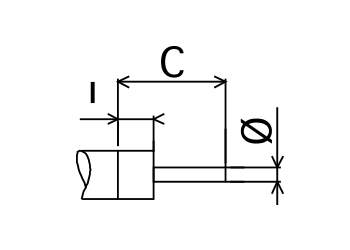

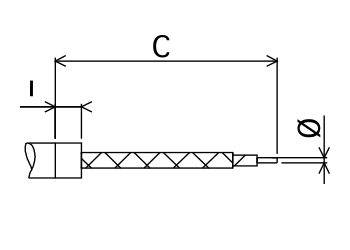

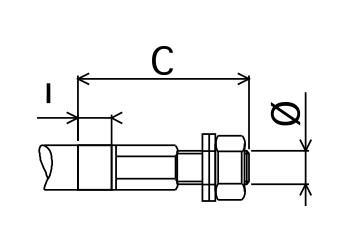

Type B 200

- PLAIN ROD

| Dimensions | Sheaths Ø | ||||||

| Ø mm | C | I | 6.5 | 8.5 | 10 | 13.5 | 16 |

| 2 | 20 | 5 | |||||

| 3.5 | 25 | 5 | |||||

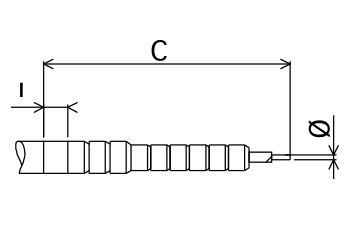

Type B 300

- BRAID OR CABLE

| Dimensions | Sheaths Ø | |||||

| section mm² | C | 6.5 | 8.5 | 10 | 13.5 | 16 |

| PVC INSOLATED COPPER CABLE H07VK 70°C | ||||||

| 1.5 | (1) | |||||

| 2.5 | (1) | |||||

| RUBBER INSOLATED COPPER H07RNF 85°C | ||||||

| 1.5 | (1) | |||||

| 2.5 | (1) | |||||

| 4 | (1) | |||||

| 1.5 | (1) | |||||

| 2.5 | (1) | |||||

| 4 | (1) | |||||

| 6 | (1) | |||||

| 10 | (1) | |||||

| SILICONE INSOLATED COPPER 180°C | ||||||

| 1.5 | (1) | |||||

| 2.5 | (1) | |||||

| 4 | (1) | |||||

| 6 | (1) | |||||

| GLASS BRAIDED COPPER 280°C | ||||||

| 1 | (1) | |||||

| 1.5 | (1) | |||||

| 2.5 | (1) | |||||

| 4 | (1) | |||||

| 6 | (1) | |||||

| INSOLATED NICKEL WIRE 700°C | ||||||

| 1.5 | (1) | |||||

| 2.5 | (1) | |||||

| 4 | (1) | |||||

| 6 | (1) | |||||

(1) Cable lenght go request

| Dimensions | Sheaths Ø | |||||

| section mm² | C | 6.5 | 8.5 | 10 | 13.5 | 16 |

| NICKEL BRAIDED NICKEL 350°C / 450°C | ||||||

| 1 | (1) | |||||

| 2.5 | (1) | |||||

| 2.5 | (1) | |||||

| 4 | (1) | |||||

| 6 | (1) | |||||

(1) Cable lenght go request

| Dimensions | Sheaths Ø | |||||

| section mm² | C | 6.5 | 8.5 | 10 | 13.5 | 16 |

| CERAMIC NICKEL WIRE | ||||||

| 1.5 | (1) | |||||

| 2.5 | (1) | |||||

(1) Cable lenght go request

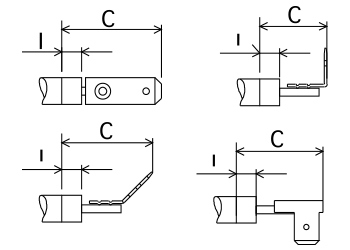

Type B 400

- 6,35 TAB

| Dimensions | Sheaths Ø | ||||

| Description | C | I | 6.5 | 8.5 | 10 |

| Straight single | 25 | 5 | |||

| carved single | 23 | 5 | |||

| Transverse single | 15 | 5 | |||

| Straight twin | 22 | 5 | |||

| Delta twin | 22 | 5 | |||

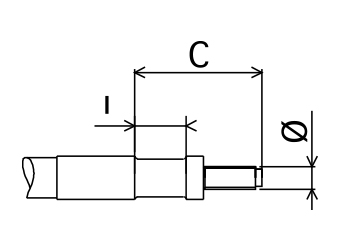

Type B 500

- FLAT TERMINAL

| Dimensions | Sheaths Ø | |||||

| C | I | 6.5 | 8.5 | 10 | 13.5 | 16 |

| 25 | 5 | |||||

| 30 | 10 | |||||

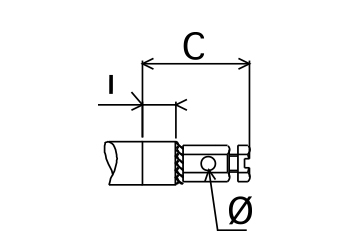

Type B 600

- THREADED TERMINAL

| Code | Dimensions | Sheaths Ø | ||||

| Ø mm | C | I | 6.5 | 8.5 | 10 | |

| LAITON : B 614-6 | M6 x 1 | 30 | 5 | |||

| INOX : B 623-6 | M6 x 1 | 21 | 5 | |||

Type B 700

- SCREW TYPE BRASS TERMINAL

| Dimensions | Sheaths Ø | |||

| C | I | 6.5 | 8.5 | 10 |

| 15 | 5 | |||

Type B 800

- BRAZABLE STEATITE

| Dimensions | Sheaths Ø | ||||||

| Ø mm | C | I | 6.5 | 8.5 | 10 | 13.5 | 16 |

| M 6 | 37 | 13 | |||||

| M 6 | 37 | 13 | |||||

| M 8 | 55 | 15 | |||||

| Use in humid conditions | watertight | ||||||

| temperature from – 60°C to + 200°C | |||||||

| defrosting resistance | |||||||

Type B 900

- BRASS PIN TERMINAL

| Dimensions | Sheaths Ø | ||||||

| Ø mm | C | I | 6.5 | 8.5 | 10 | 13.5 | 16 |

| 6 | 22 | 5 | |||||

| 6 | 22 | 5 | |||||

- According to CE European directives and CE market (for Europe)

- ATEX/IECEx certificate for component or system

- EAC CU TR, c CSA us (NEC 505)

![]()

Electrical tests

- Power test by cold resistance measurement. Allowed tolerance: -5% and +10% of the nominal resistance value.

- Insulation test, direct voltage 500 V, mini cold value is > 100 Megohms

- Dielectric test, (2U + 1000 V) x 1,2 during 1 second

- The stray current and the hot dielectric rigidity can be measured on a sample at operating temperature (on request).

- 100% of the heating elements are tested before shipment (final control)

Mechanical tests

- Visual inspection

- X-ray test (if required)

Dimensional test

- Critical dimensions are tested

- Marking: specific customer marking on each heating element

- Specific connection terminals (on request)

- Fixing part such as connectors (on request)

CETAL deliver straight heating elements to many customers in different industries where the reliability and the quality is a must.

The heating element being the active part (“engine”) of the final product or within the customer process, our customer make the choice of reliability!